Introduction to Wastewater Screening Efficiency

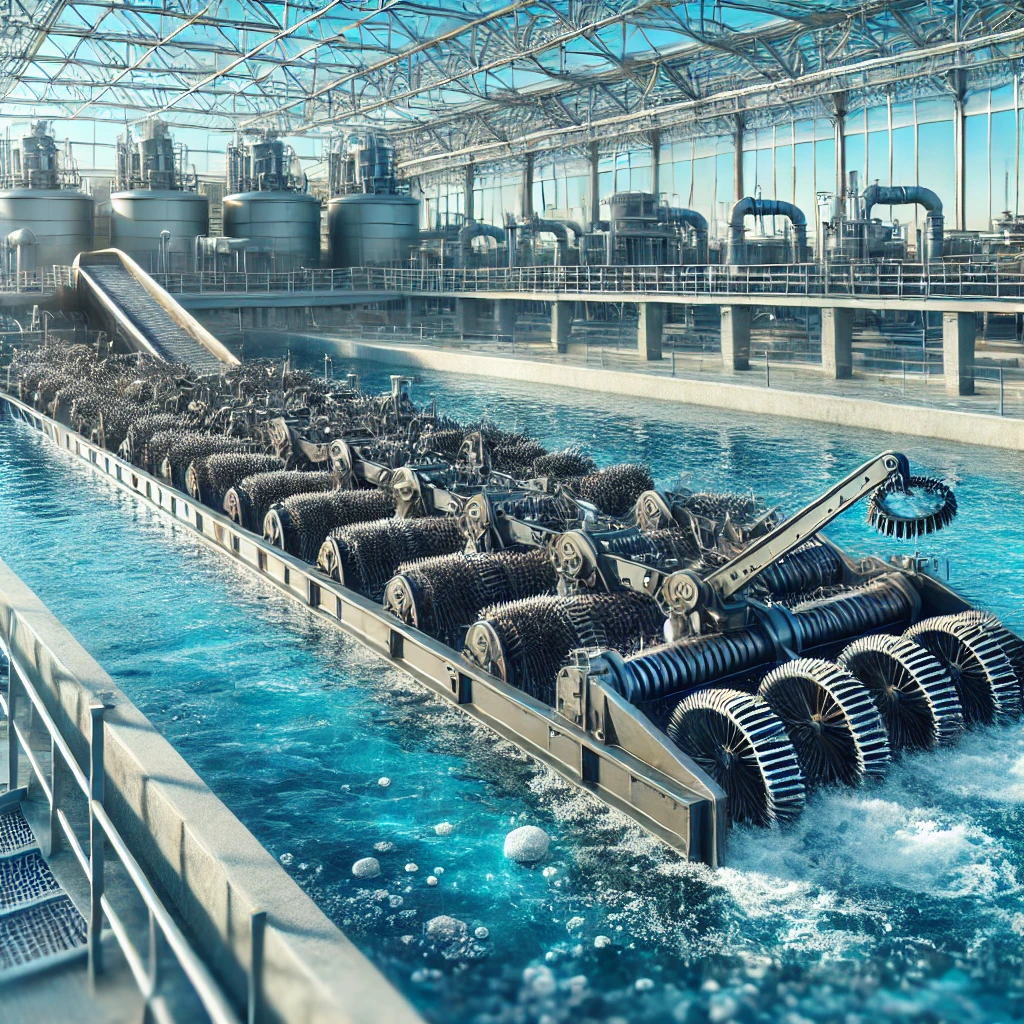

Wastewater treatment is crucial for maintaining clean and safe water supplies. Among the various stages of wastewater treatment, screening plays a vital role in removing large solids and debris from the water. One innovative tool that significantly enhances this process is the chain rake. This article delves into how chain rakes improve wastewater screening efficiency, their benefits, and their applications in modern wastewater treatment plants.

The Basics of Wastewater Screening

What is Wastewater Screening?

Wastewater screening is the first step in the treatment process, where large objects such as plastics, rags, and other debris are removed from the wastewater. This prevents damage to the subsequent treatment processes and ensures smooth operation. Effective screening is essential for the overall efficiency of a wastewater treatment plant.

Types of Screening Systems

Various screening systems are used in wastewater treatment, including bar screens, drum screens, and fine screens. Each system has its unique advantages and is chosen based on the specific needs of the treatment plant. Chain rakes, a type of mechanical screen, are increasingly popular due to their efficiency and reliability.

Understanding Chain Rakes

What are Chain Rakes?

Chain rakes are mechanical devices used in wastewater treatment to remove debris from screens. They consist of a series of rakes attached to a chain, which continuously moves along a set path, collecting and removing debris from the screening surface. This automated process ensures a consistent and efficient removal of solids.

How Chain Rakes Work

Chain rakes operate by moving vertically or horizontally across the screen. As the chain moves, the rakes scrape off accumulated debris and carry it to a designated discharge point. This continuous movement prevents clogging and maintains the screening process’s efficiency. The debris is then collected and disposed of, ensuring the screens remain clean and functional.

Benefits of Chain Rakes in Wastewater Screening

Enhanced Efficiency

One of the primary benefits of chain rakes is their ability to enhance screening efficiency. By continuously removing debris, chain rakes prevent blockages and ensure the screens operate at optimal performance. This leads to better overall treatment efficiency and reduces the risk of system failures.

Reduced Maintenance

Chain rakes require less manual intervention compared to traditional screening methods. The automated nature of chain rakes means that maintenance staff spend less time cleaning screens and more time focusing on other critical tasks. This reduction in manual labor not only saves time but also lowers operational costs.

Improved Reliability

Chain rakes are designed to handle high debris loads and operate continuously. Their robust construction and reliable performance make them ideal for use in demanding environments. The consistent operation of chain rakes ensures that wastewater treatment plants can rely on them for effective screening, even under heavy loads.

Cost-Effective Solution

While the initial investment in chain rakes may be higher than that in other screening methods, the long-term benefits make them a cost-effective solution. Reducing maintenance costs, increasing efficiency, and improving reliability contribute to significant savings over time.

Applications of Chain Rakes in Wastewater Treatment

Municipal Wastewater Treatment Plants

Municipal wastewater treatment plants are the primary users of chain rakes. These facilities handle large volumes of wastewater from residential and commercial sources. Chain rakes help maintain efficient screening and ensure the smooth operation of the entire treatment process.

Industrial Wastewater Treatment

Industries generate wastewater that often contains large amounts of debris and solids. Chain rakes are used in industrial wastewater treatment plants to screen and remove these materials effectively, protecting downstream equipment and processes. This is particularly important in industries such as food processing, manufacturing, and chemical production.

Stormwater Management

During heavy rainfall, stormwater systems can become overwhelmed with debris. Chain rakes are employed in stormwater management systems to screen out oversized objects and prevent clogging. This helps maintain the efficiency of the drainage system and to avoid flooding.

Key Features of Modern Chain Rakes

Automated Operation

Modern chain rakes are equipped with automated controls that allow for continuous operation without manual intervention. Sensors and monitoring systems ensure that the rakes operate efficiently and respond to varying loads of debris.

Durability and Robustness

Chain rakes are built to withstand harsh conditions and high debris volumes. The materials used in their construction are resistant to corrosion and wear, ensuring a long service life and reliable performance.

Customizable Designs

Chain rakes can be customized to fit the specific needs of a wastewater treatment plant. Various sizes, configurations, and rake designs are available to ensure optimal performance for different applications.

Internal Linking

To learn more about other wastewater treatment technologies, visit our article on advanced filtration methods. Additionally, our comprehensive guide on municipal wastewater treatment processes provides further insights into the various stages of treatment.

Conclusion

Chain rakes are a vital component in modern wastewater treatment, significantly enhancing screening efficiency. Their ability to continuously remove debris, reduce maintenance needs, and improve reliability makes them an excellent investment for wastewater treatment plants. By adopting chain rakes, facilities can ensure smoother operations, lower costs, and better overall treatment performance.

For further information on how chain rakes can benefit your wastewater treatment plant, contact our experts today.